Worker-Driven Triangle of Prevention Program Helps Improve Workplace Health and Safety in Oil Industry

During the 1980s and 1990s numerous catastrophic fires, explosions and toxic releases plagued the U.S. petrochemical industry, causing workers to suffer horrific deaths and injuries.

Consultant-driven safety programs, where workers and their behavior were seen as the predominate cause for occupational injuries and illnesses, proliferated during these decades.

Tired of this behavioral safety, blame-the-worker approach, the Oil, Chemical and Atomic Workers (OCAW) Union in the mid-1990s enlisted a team of rank-and-file members who were health and safety activists with experience on the shop floor to develop a new system.

Behavioral Shortfalls

OCAW member Glenn Erwin was on that team, and he and the others observed that if there was an incident, management’s first reaction after conducting an investigation was to blame employees and discipline or terminate them.

This employee focus ignored other factors that cause incidents, such as inadequate design and engineering of systems, delayed maintenance and inspection, mitigation and warning systems that fail, lack of or inadequate training, pressure to take shortcuts and ignore procedures to reach production goals, inadequate documentation when a production change is made, management decision to ignore safety warnings, and inadequate personal protective equipment.

Management’s view was that health and safety was its prerogative, so workers were not allowed to investigate incidents with company staff. No one felt ownership over the company safety programs. However, companies gave the illusion of control through employees watching others conduct their work tasks to see if they were working safely.

Another problem the team saw with these behavioral-based health and safety programs was that management focused on slips, trips, falls, and “struck-by” incidents. Companies measured safety narrowly through the OSHA recordable rate, which only counted worker injuries.

When a disaster occurred—like an explosion, fire and major release—management finally paid attention to process safety. Process safety concerns managing the integrity of operating systems, assets (equipment) and processes that handle hazardous substances to prevent unplanned releases which could result in major incidents.

Inevitably, nothing ever was learned from these incidents and they would be repeated.

Breaking the Mold

Erwin and his team created a pro-active program which the OCAW dubbed the “Triangle of Prevention” (TOP). TOP has three sides: union design and leadership, systems of safety training and investigations, and comprehensive tracking of results.

Erwin and his team created a pro-active program which the OCAW dubbed the “Triangle of Prevention” (TOP). TOP has three sides: union design and leadership, systems of safety training and investigations, and comprehensive tracking of results.

The team devised the program so that workers and their union have ownership over their plant’s health and safety conditions since they operate the plant, day in and day out. They know when a piece of equipment, a unit and/or a process is not running correctly and could cause a catastrophic event.

By being involved in TOP, workers help management operate safely to avoid catastrophic incidents that cost lives, injuries, disabilities, lawsuits and regulatory fines.

Companies and grants pay for TOP; no union dollars go into the program. It is a union benefit that all employees receive. The Tony Mazzocchi Center (TMC) administers TOP and conducts trainings. Glenn Erwin served as TMC’s TOP program coordinator and retired in 2012.

Systems of Safety

TOP’s foundation is the seven systems of safety: design and engineering, mitigation devices, maintenance and inspection, warning devices, training, procedures, and personal protective equipment.

TOP’s foundation is the seven systems of safety: design and engineering, mitigation devices, maintenance and inspection, warning devices, training, procedures, and personal protective equipment.

TMC trains workers in the systems of safety and, in turn, they learn to train others, to conduct near-miss and incident investigations, and to become site-based program leaders, including as TOP representatives.

Focus is on establishing a health and safety culture, so everyone in a plant—workers, managers and non-represented staff employees—is given an 8-hour initial TOP awareness training, followed up with annual 4-hour refresher training. TOP worker-trainers also give systems of safety training to contractors.

Workers are encouraged to report near misses because companies in the TOP program agree to a no-discipline policy for reporting or being involved in a near miss.

When near misses and incidents occur, they are viewed as happening because of multiple causes, including one or more root causes, each of which is linked to a failure in one or more of the seven systems of safety. It is a holistic approach.

TOP investigators include union workers and management using TOP investigation methods such as logic tree diagramming. This method applies the systems of safety to analysis of what happened in a near miss or incident so the root causes can be uncovered.

“Locals have applied logic tree diagramming to settle grievances when companies want to discipline workers involved in an incident,” said John Scardella, TMC program administrator. “Anyone can learn this method, and it can’t be manipulated. The logic tree is fact-based, no matter the outcome.

“Identifying accidents is not enough. Finding and fixing hazards is not enough. You need to identify root causes,” he added.

Tracking and Sharing

TOP involves comprehensive tracking of systems of safety performance. Near misses, process upsets, releases, incidents and root causes are tracked to identify system failures and trends.

Once root causes are discovered, TOP personnel recommend solutions to eliminate or control the hazard(s) using the highest system of safety possible (design and engineering). Recommendations are tracked to completion so workers see positive results from their reporting of near misses and incidents.

The last step of the TOP process is to share the lessons learned from investigations of near misses and incidents across a site, across a company’s entire operations and across the industry. This process is critical because it helps prevent near misses and incidents from reoccurring so workplaces and surrounding communities are safer, injuries prevented and lives saved.

For More Information

If you are interested in the TOP program, you can contact TOP Program Coordinator Steve Doherty, sdoherty@uswtmc.org or 412-562-2561 and TMC Program Administrator John Scardella, jscardella@uswtmc.org or 412-562-2582.

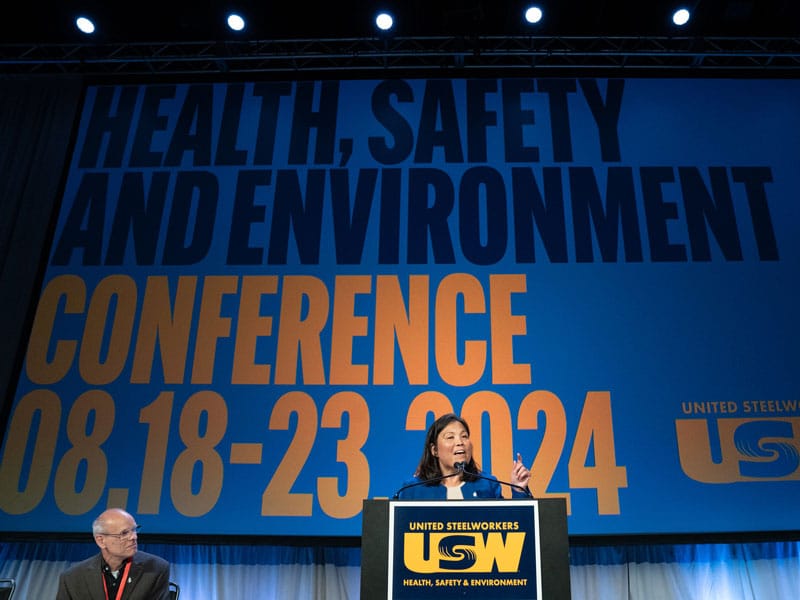

PHOTO

TOP: Louis Tharp, LU 265, Shell Chemical, Saraland, Ala.; Lori Aldridge Smith, LU 9-1535, Essity (SCA), Barton, Ala.; Carmine Frangella, LU 13-750, Shell Chemical, Norco, La.; John Henninger, LU 10-1, Philadelphia Energy Solutions, Phila., Pa.; Jeff Wright, LU 13-423, Motiva, Port Arthur, Texas; Kevin Theriot, LU 13-750, Shell Convent, La.; Jaret Marquez, LU 13-487, Valero, Sunray, Texas; and Matt Velker, LU 912, PBF Toledo Refining Complex, Oregon, Ohio. Photo by Mike Hancock, LU 9-562 retiree.

BOTTOM: Gerard Borne, LU 13-750 TOP representative, Shell, Norco, La. Photo by Mike Hancock, LU 9-562 retiree.

By clicking Sign Up you're confirming that you agree with our Terms and Conditions.

Recent News Articles

Want to Learn More?

See how the USW is making a real difference in our communities and our workplaces.