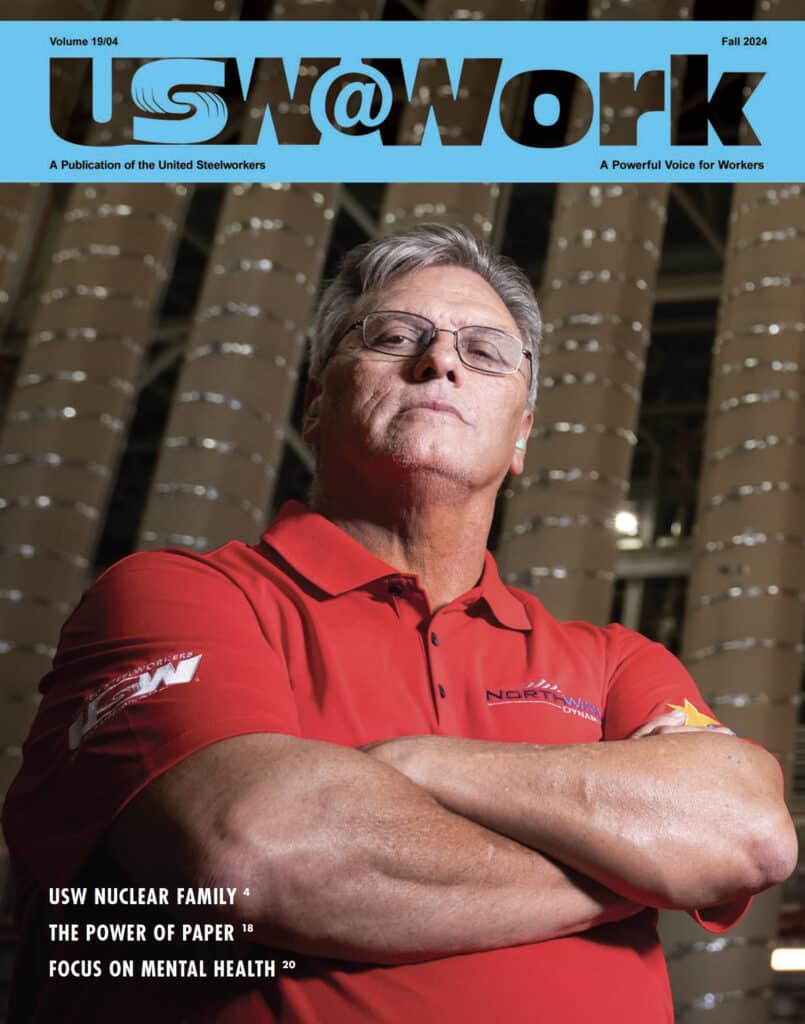

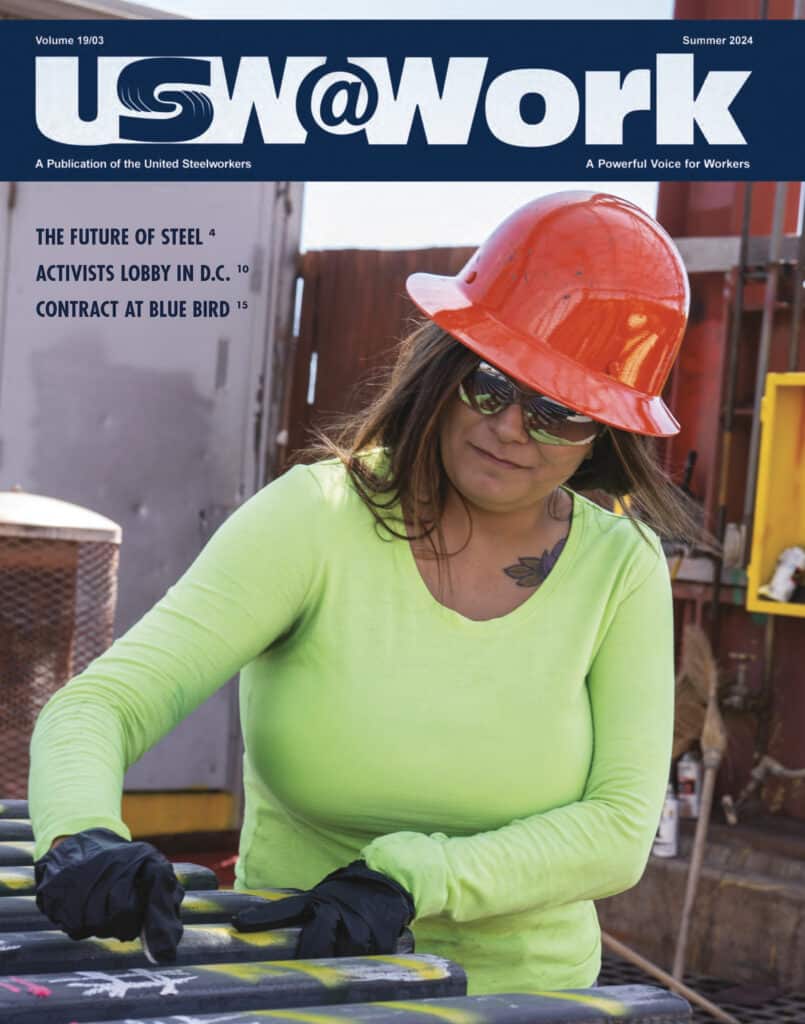

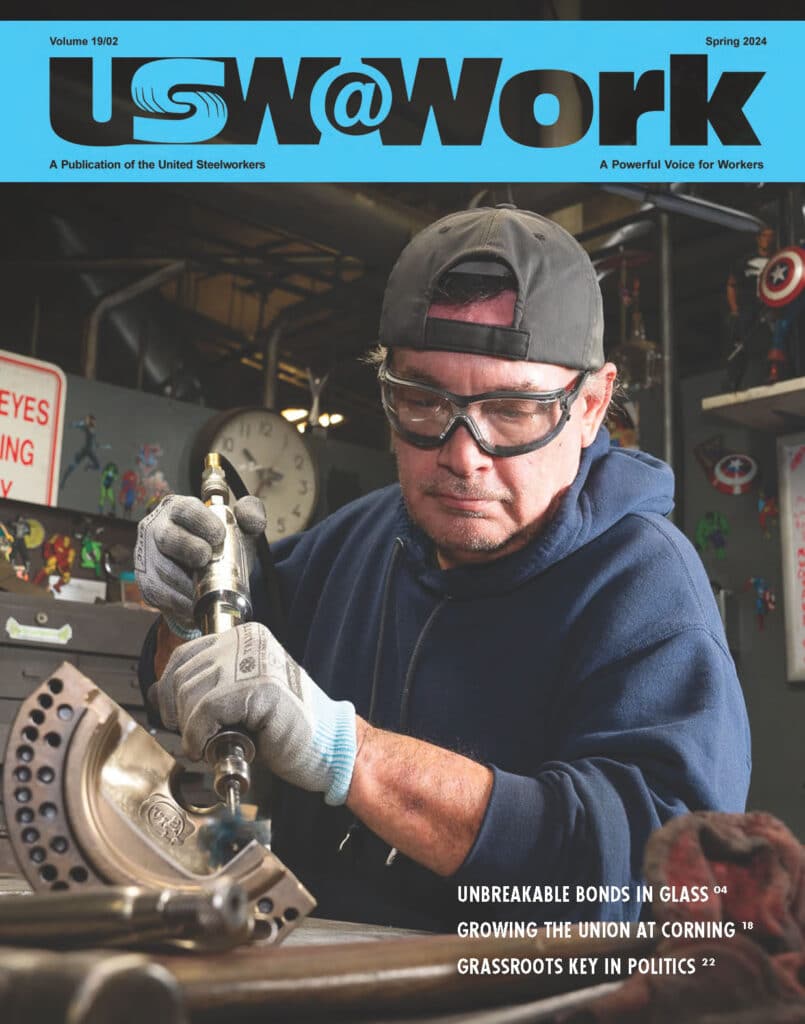

USW@Work

Our union's quarterly magazine shines a spotlight on the important work USW members are doing—in their workplaces, at the bargaining table, in their communities and beyond.

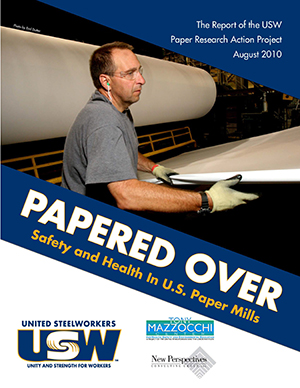

USW Publications

Our union produces a wide array of resources to help keep members up-to-date on important topics like health and safety, international trade, legislative initiatives and other ongoing work.

Need More Information?

Contact Us!

We’re here to assist. Get in touch if you have any questions or concerns or would like more information about USW publications and other resources.